CUSTOMISED CLEANING SYSTEM INCREASES QUALITY

With customised extraction, painting and heating systems for woodworking companies as well as air technology components for mechanical engineering companies, LBH has grown into a company with 80 employees. An unloved job was always the degreasing of the up to 3 metre large parts before the painting process. The installation of a customised BUPI CLEANER® POWERTEC cleaning system brought not only better cleaning results but also increased efficiency by parallelising the cleaning and painting processes.

LBH Lüftungs- Behälter- u Heizungsanlagenbau GesmbH, based in Wolfsegg, Upper Austria, produces customised extraction and painting systems for woodworking companies as well as heating systems for the thermal utilisation of the extracted chips and supplied wood chips. Mechanical engineering companies also use LBH’s know-how in sheet metal processing and ventilation construction. They purchase fans and extraction systems for integration into their machines.

Paint preparation as a back-breaking job

Before they enter the paint booth, the parts have to be cleaned and degreased. “For 25 years, this cleaning process was done by hand,” says LBH Managing Director Christian Greifeneder. “A not very attractive job, which on top of that often had to be done under time pressure outside normal working hours. A real back-breaking job.” At this point in the production process – a bottleneck – a change of method was necessary.

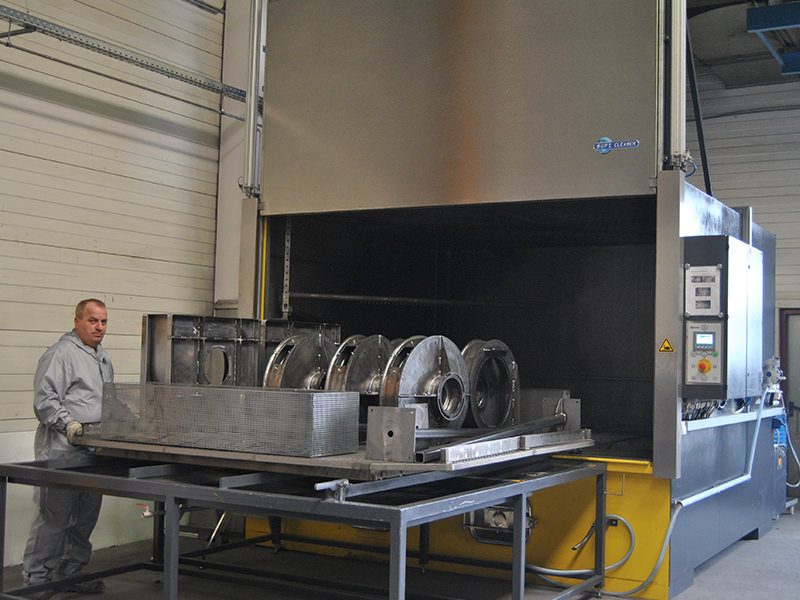

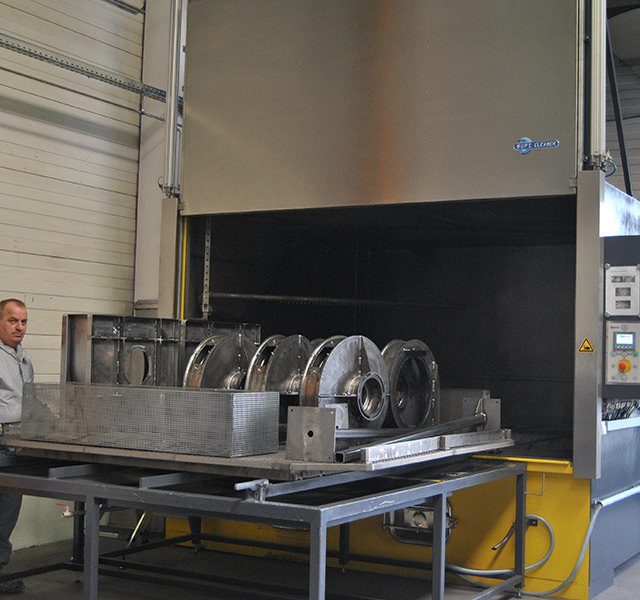

On the occasion of a factory visit at BUPI Golser, the BUPI CLEANER® POWERTEC 7HP chamber washer in lift-door design was able to convince with an excellent result during the test cleaning runs with parts brought along. “Since we wanted to clean at least 80 % of our finished parts by machine, we needed a workspace that could accommodate 3-metre-long parts made from standard large-format panels,” says plant manager Christoph Kurzböck. “However, we were also able to get an idea of BUPI Golser’s expertise in building special designs during the factory tour.”

Oversized eco design

The edge dimension of the square grating on the LBH machine is 2,250 mm instead of the 1,700 mm of the largest standard version 7HP. Replacing the electrical heating for the cleaning medium with heat exchangers for connection to the company’s own hot water network saves the company electricity costs of approx. € 9,000 per year. A compressed air diaphragm pump conveys any liquid residues back into the cleaning agent tank and ensures that no escaping water vapour affects the climate in the factory hall.